Welcome to Shandong Yichuan Steel Co., Ltd.

2024-05-31

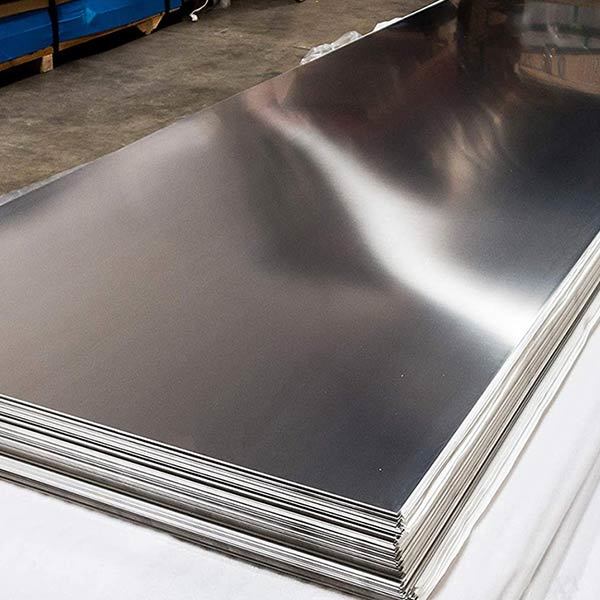

Steel plate is a flat, rectangular-shaped sheet made from steel, a versatile and strong material widely used in various industries. Its production, maintenance, and applications are crucial to ensure optimal performance and durability in various engineering projects. This article provides a professional explanation of the production processes, maintenance strategies, and diverse applications of steel plates.

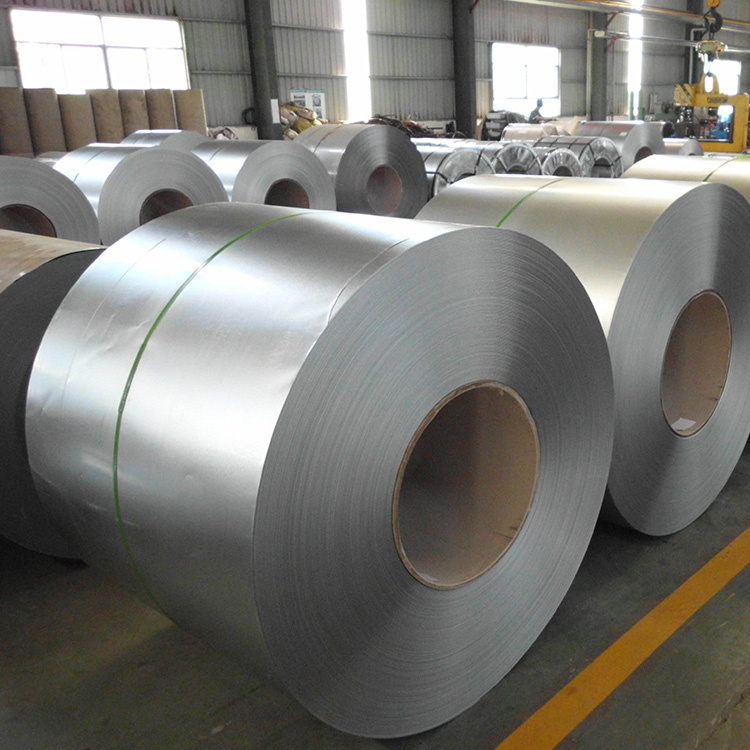

Steel coil is a significant product in the steel i

2024-05-31

In the production process, steel coils are created by passing molten steel through a series of rolling mills. These mills shape the steel into thin, flat sheets, which are then wound onto a coil. The coils can be produced in different sizes and thicknesses, depending on the specific requirements of the industry and application.

Corrugated board finds widespread applications across various industries.

2024-05-31

The production of corrugated board involves several steps. First, the liners, which are made from recycled paper or virgin fibers, are processed and coated with starch to enhance their strength. Next, the flute is formed by passing a paper web through a corrugating machine, which creates a series of parallel ridges and valleys. The liners are then glued to the flute, creating a sturdy and flexible corrugated board. Finally, the board is cut into desired sizes and shapes.

Color-coated rolls, also known as color-coated steel coils

2024-05-31

In terms of production, color-coated rolls typically undergo a series of steps. First, the base steel is cleaned to remove any impurities and then treated with a chemical conversion coating to enhance its adhesion with the paint. Next, a primer is applied to ensure better paint adhesion and protection. After that, the organic paint is evenly coated onto the surface of the rolls using advanced coating techniques such as roller coating or spray coating. Lastly, the coated rolls are cured at a specific temperature to ensure proper drying and adhesion of the paint.

2024-05-31

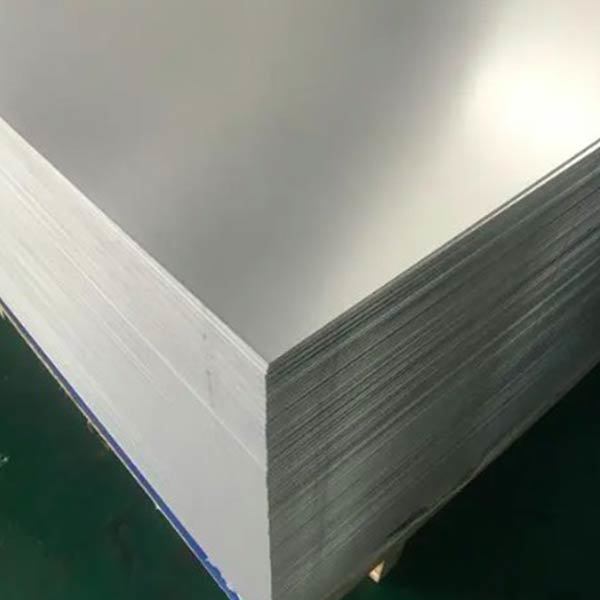

One of the key benefits of aluminum plate is its lightweight nature, making it easy to handle and transport. Despite its lightweight, aluminum plate is also incredibly strong and resistant to corrosion, making it suitable for a wide range of applications.

2024-05-31

The production process of aluminum tube involves several steps. It starts with extracting aluminum from bauxite ore through a process called electrolysis. The extracted aluminum is then melted and cast into billets or logs. These billets are then heated and extruded through a die to form the desired shape and size of the tube. The extruded tube is then cooled, cut to the required length, and further processed to meet specific requirements.

CONTACT US

Tel : +86-13589460884

Tel : +86-13563017320

WhatsApp : +86-13589460884

WhatsApp : +86-13563017320

Wechat : 13589460884 13563017320

Email : ariel@yichuansteel.com

GET A FREE QUOTE

Copyright : Shandong Yichuan Steel Co., Ltd. SEO 300.cn Business License