Galvanized iron wire

Category:

Iron wire

Keywords:

Iron wire

Galvanized iron wire

Iron wire production has developed earlier due to its simple process and wide application. Iron wire or steel wire (corresponding to "wire mesh enterprises") is a cold processed product of steel wire, and the materials used are generally high-quality carbon steel or stainless steel. Usually, it is necessary to go through several procedures such as shell peeling, acid washing, water washing, saponification, drying, drawing, annealing, cooling, acid washing, water washing, galvanizing, packaging, etc. to produce iron ingots (steel ingots) for making iron wire (steel wire).

The production of iron wire and steel wire generally adopts wire drawing process and galvanizing treatment. In 1976, Guangzhou Galvanized Iron Wire Factory was the first in China to successfully apply new technologies such as electrolytic pickling, high-pressure washing, and card electric drying to test the continuous production of wire drawing lines. This changed the wire drawing process from intermittent production to continuous production, weakened labor intensity, and reduced metal consumption. At that time, domestic wire factories were already able to produce products such as steel wire ropes, spoke low bar steel wires, umbrella steel wires, spring steel wires, and bicycle saddle spring steel wires. In the 1980s, hot-dip low-carbon steel wire, fan mesh cover steel wire, carbon structural steel wire, and bed surface steel wire were also introduced for nailing. After annealing, the elongation of the iron wire is increased, making the product more flexible and expanding the applicability of the iron wire. It is widely used in wire mesh production through electroplating, hot-dip galvanizing, copper plating, and other methods. The binding of building steel bars and the weaving of the iron wire mesh can be done by first weaving and then plating, and first plating and then weaving. The processed iron wire mesh or steel wire mesh has good anti-corrosion and antioxidant properties, and can be used for reinforcement, protection, and insulation in industries such as construction, petroleum, chemical, aquaculture, landscaping protection, and food processing.

Packing and shipping

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements. We can provide container or bulk transportation, road, rail or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation.

FACTORY

APPLICATION AREAS

Asia, and have been well received by domestic and foreign customers. The products are widely used in water conservancy projects, military equipment, construction industry, aerospace, automobiles, home appliances and other fields.

CUSTOMER VISIT

HONOR

Cold Rolled Steel Sheet

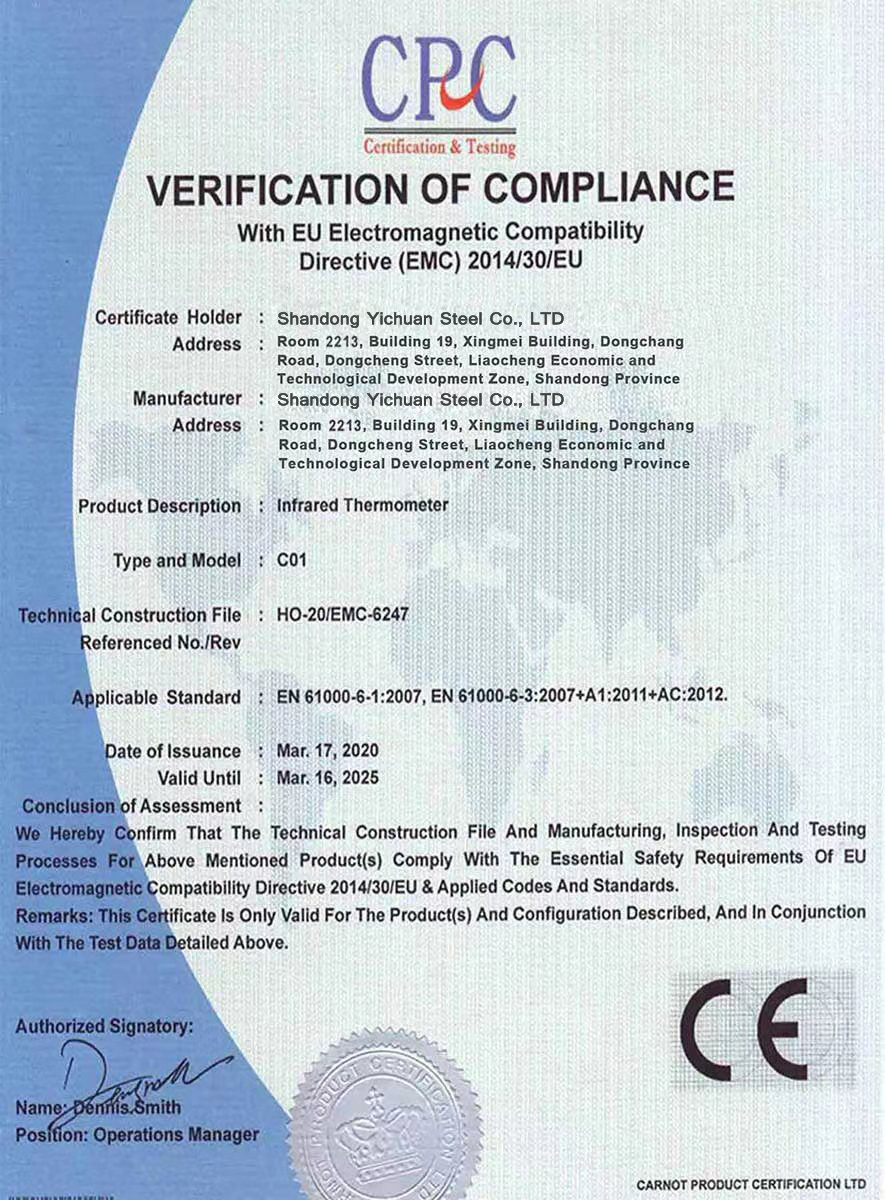

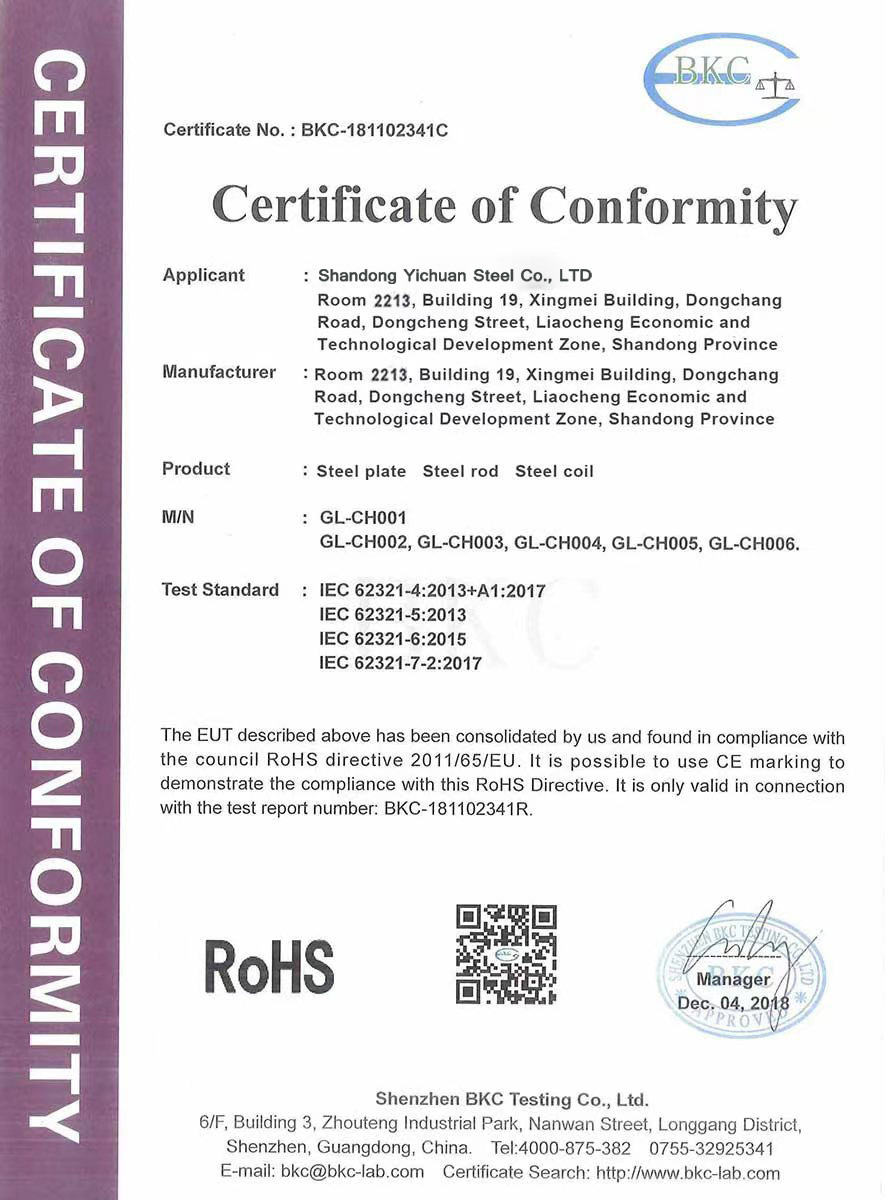

Certificate

Certificate

Certificate

Certificate

Related Products